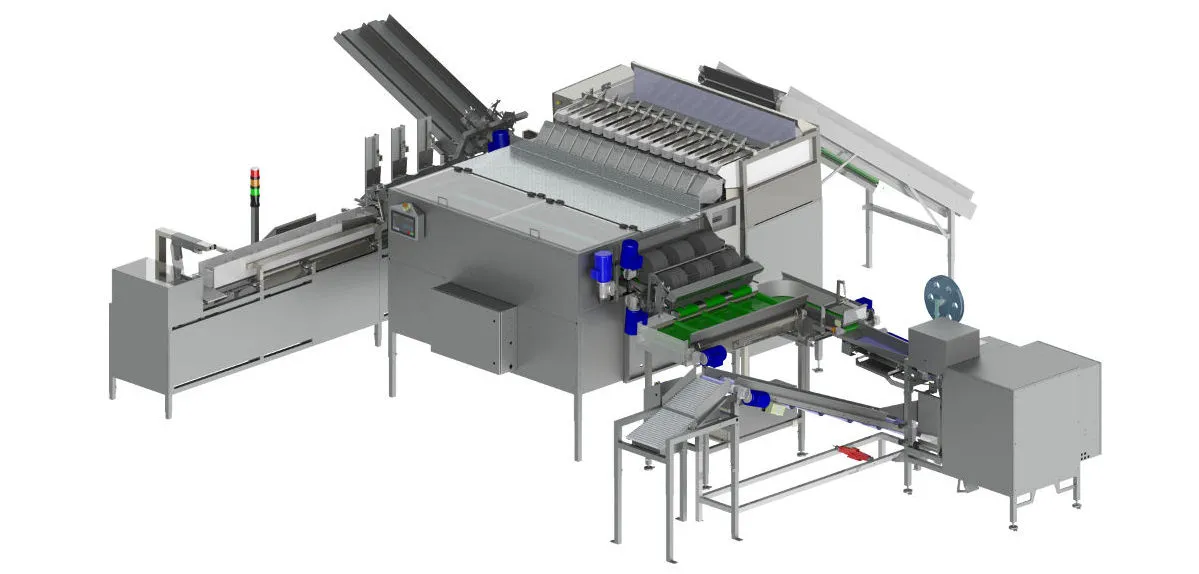

Weighing-/packaging-line for both punnets and wicketed bags

Delivery: April 2014

Product: Apples and pears

Portion sizes: 1,5 kg

Packaging: Punnets and wicketed bags

Capacity:

| Apples | : Up to 45 portions/min. |

| Pears | : Up to 40 portions/min. |

Machines included:

- h2014AP

- Punnet machine, model NBM45AL

- PEB40AE/KL + PEB40AE/KL

- CW5000 Check Weigher

Challenge

Our customer required different packaging options; they needed to pack their products in both punnets and wicketed bags.

Solution

With this in mind, Newtec delivered a flexible solution with a high capacity and a very gentle handling from infeed to outlet of two fragile products with two different packaging options.

We chose our multi-head weigher - model h2014AP, as it is specially designed for the handling of both apples and pears. It is constructed with 14 weigh-heads and designed with an extremely low drop height. The weigher conveys the portions at a speed of up to 45 portions/min. without any direct drops to the packaging machine. What makes it particularly suitable for fragile products, such as apples and pears, is the slide that very gently feeds our punnet machine - model NBM45AL.

The punnets are automatically unstacked and the empty punnets are automatically conveyed to the filling stations.

At the filling station, the portions are gently placed into the punnets by the specially designed soft-fill system. Alternatively, the portions can be conveyed to the other side and packed in wicketed bags by our apple and pear bagger.

Our solution has successfully been in operation since 2014.

Weighing and packaging of mixed, fresh, cut fruits in trays

Delivery: November 2016

Product: Mixed, fresh cut fruits

Portion sizes: 220 - 400 g

Packaging: Trays

Machines included:

- 6 x Newtec Mini Weighing Machines, Model 2008PCM

Challenge

Mix of up to four different fruits in ONE tray with a weight of 220-400 g.

Each tray contains:

Approx. 50 g green melon

Approx. 50 g pineapple

Approx. 40 g yellow melon

The remaining amount - up to 220 g (80 g) are grapes

Solution

The solution includes 2 lines - 4 x 2008PCM and 2x 2008PCM which are connected. The customer pre-defines a recipe on a machine and the software ensures that the target weight is correct.

The 3 products mentioned above, are weighed as close to target weight as possible and subsequently topped up with product no. 4 (grapes).