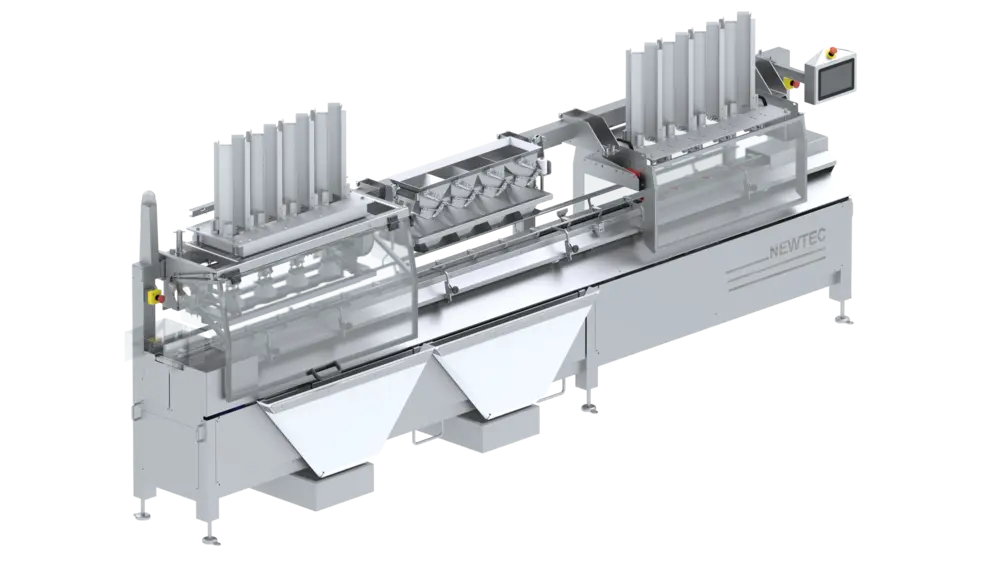

HSCF - High Speed Container Filler

HSCF

For various ready-to-eat products in various types of containers

Flexible dispenser systems and punnet conveyors

- Handle a broad range of packaging types and sizes.

- Adjustable flight distance

You save valuable downtime minutes with quick changeover for various container sizes.

Newtec’s High Speed Container Filler is equipped with a tool for each container type and while covering complex functions each tool is very easy to change from running one container type to another. E.g. it is easy to change from clamshell trays to buckets, because the following three units are exchangeable; the denester, the filling chute and the closing unit.

Furthermore the packaging machines are connected to our information and productivity tool WebServices for remote servicing and for capturing production data. Furthermore, the solutions are MachineLink enabled which means that recipe change and start/stop is possible from only one touchscreen, either on our weighing machine or our packaging machine.

Applications

Various convenience food such as:

- Cherry tomatoes and other fresh vegetables

- Mixed nuts

- Healthy candy

- Other ready-to-eat products

Weighed and filled in various container types and sizes.

Advantages

- High flexibility (container type and size)

- High speed – up to 100 containers per min. (depending on container type and capacity of weighing machine)

- High flexibility with low changeover time

- Gentle product handling – also for fragile and delicate products

Your Advantages

- Smooth and fast operation

- Optional lid closing unit

- Easy access for cleaning and service

- Single touchscreen operation controlled from weigher panel

Newtec Software

- Intuitive user interface

- Informative and upgradeable

- Same user interface on all weighing and packaging machines

Filling System for Cups, Buckets, Punnets & Clamshell trays

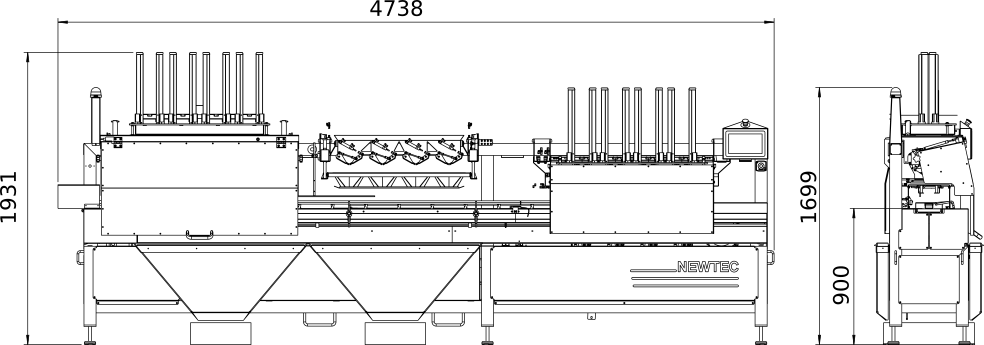

| Speed: | Up to 100 containers per min. (depending on container type and capacity of weighing machine) |

|---|---|

| Capacity: | Portion sizes up to 1000g |

| Material: | According to the EU rules on food contact materials |

| Air requirement: | Connection: 3/8” Min. pressure: 6 bar (0.6 Mpa) Consumption: 250 NL/min. |

| Electrical requirement: | 3x230 VAC or 3x400 VAC (N) PE 50/60 Hz 2.5 kW |

| Environment: | 5ºC – 40 ºC |

| Weight: | Approx. 800 kg |

Contact

Please contact your local representative for more information. See more