同时按照质量,尺寸和形状

How can our optical sorting machine for carrots optimise your production?

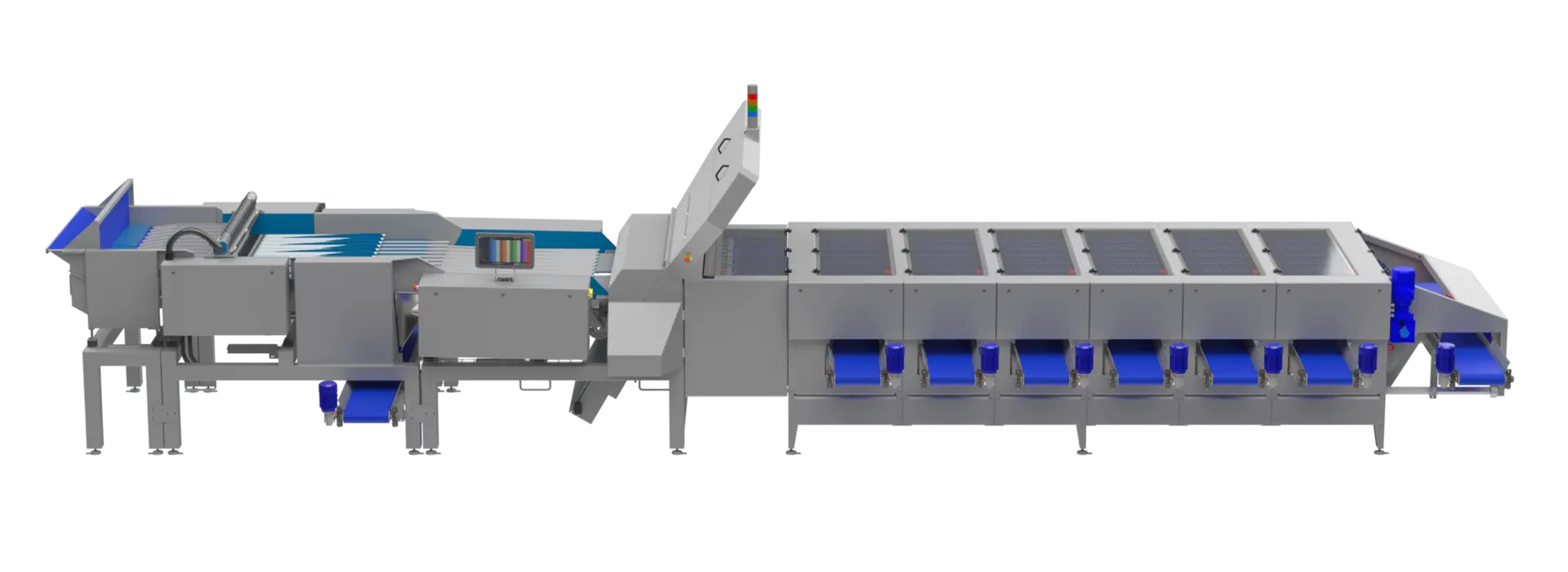

Newtec's optical sorting machine for carrots, model Celox-C-UHD, is designed to sort carrots by size, shape and quality in a single-stage process. The machine sorts washed carrots directly, eliminating the need for pre-grading and minimising the need for manual labor, whilst ensuring consistent quality output and high throughput.

Up to 16 categories of products can be sorted out simultaneously. Sorting criteria for these categories are instantly customisable according to the current needs. Premium product selections can effortlessly be sorted out of bulk produce.

Being completely configurable by the operator or factory manager the sorting machine permits near-instant turn-around time and unparalleled flexibility. Additionally the machine collects detailed real-time product data which is available with Newtec WebServices. The same data can optionally be integrated in your own business IT-systems for further analysis.

产量

Celox-C-UHD 胡萝卜分选机

4 lanes: up to 50,000 carrots/h

8 lanes: up to 100,000 carrots/h

12 lanes: up to 150,000 carrots/h

Your advantages

- Quality, size and shape sorting in one machine

- Accurate selection of high-value products

- Consistent quality output

- No need for mechanical pre-grading

- Gentle product handling

- Robust stainless steel construction

- Modular design for future extension (up to 16 categories/outlets)

- WebServices , our data collection system, enables capturing of complete product information and remote servicing.

进料区

The infeed section gently singulates products and conveys them into the camera section. It is computer controlled to ensure optimum throughput on all lanes.

摄像区

Our in-house developed high speed camera inspects each product from three angles, each covering 120 degrees to capture accurate data on size, shape and surface quality. Every product is evaluated according to the grading parameters chosen by the operator.

分选区

Products enter the Spinaflex™ section after passing through the camera section. The Spinaflex™ belt directs each product to the correct outlet, ensuring product integrity with minimal drop heights.

The Celox-C-UHD handles products very gently.

- The product drop height is very low.

- The Spinaflex™ system routes products at low speed with minimum amount of shocks.

We believe that the machine we've got now which is the latest model - it ticks all the boxes. The quality of the actual machine itself, the reliability of it, the way it handles the product, the quality of the cameras, it is just well above our expectations of what I think a machine could or should do.